Wall Systems

SRK's Precast Counterfort Retention System (PCRS) has a long history of innovation with engineered solutions, designed to bring sustainability and precision as well as ease, safety, and speed of installation. As a counterfort wall system, SRK simplifies on-site installation and eliminates shoring while providing the performance required by the most demanding roadway, railway and sea wall applications. Read more below to learn about SRK's innovative solutions.

Roadway, Railway & Waterway

The Precast Counterfort Retention System (PCRS) is designed in accordance with American Railway Engineering and Maintenance-of-Way Association (AREMA), American Association of State Highway and Transportation Officials (AASHTO) and State Department of Transportation (DOT) codes, based on load resistance factor designs with service level checks where required by code.

Balboa Station

Rose Creek Bike Path - dry

Rose Creek Bike Path - during storm event

Pikes Peak COG Railway

A Long History of Reliability

The PCRS wall has over 30 years of history that continues to provide clients with innovative high-quality and cost-effective precast designs for railroad, highway, and seawall applications with a flawless track record.

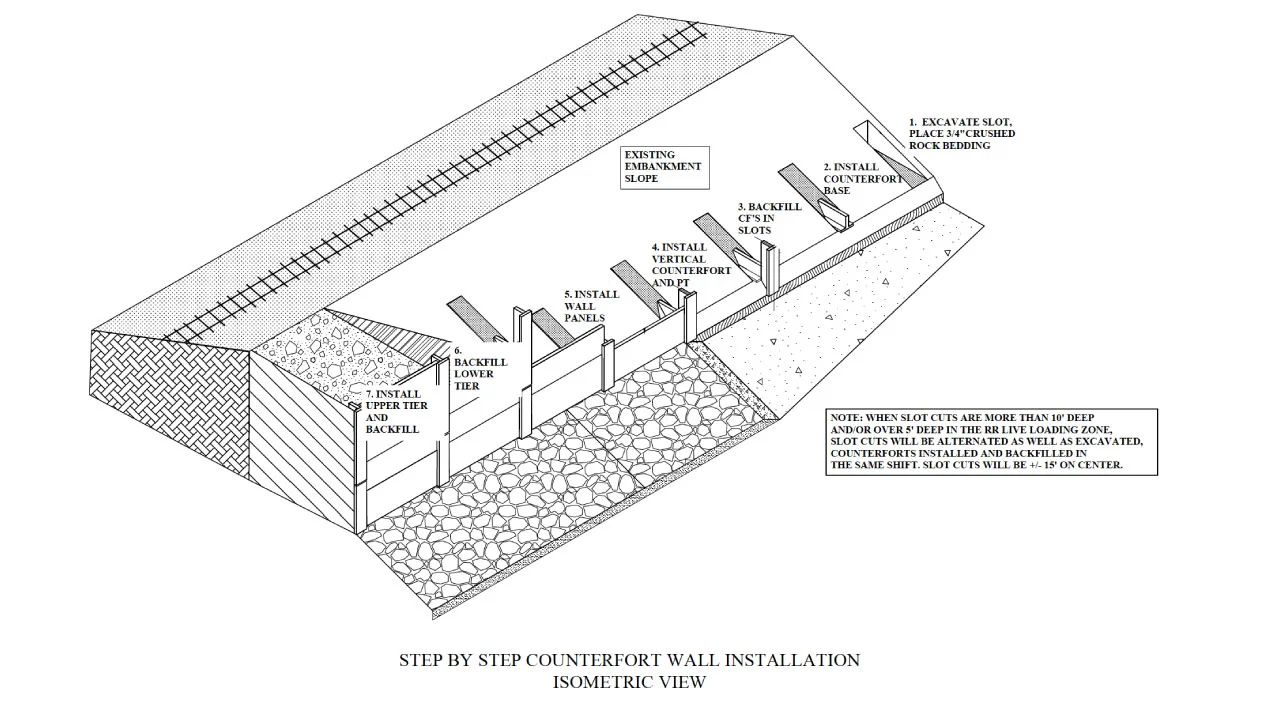

Building & Installation

Eliminates shoring

One of the key features of the PCRS wall is the elimination of shoring normally associated with the installation of retention walls. By utilizing the "slot-cut" installation method, temporary shoring, which may be required for other wall types, is eliminated. Therefore, the overall wall cost and construction time is greatly reduced compared to other wall options. The horizontal counterforts are placed in excavated slots that are cut into an existing embankment so that shoring is not required. In addition, counterfort foundations reduce the wall bearing pressures, and result in less overall settlement potential.

Unique and simple system

SRK's Proprietary Wall System (PCRS) wall offers a unique and simple solution to multiple construction challenges. The flexible wall has no mechanical connections, yet has very strong and rigid structural component. High quality precast concrete is used resulting in high durability and superior corrosion resistance. The horizontal counterforts internally stabilize the wall, providing pullout resistance against the lateral earth pressure exerted on the retaining wall internally stabilize the wall, providing pullout resistance against the lateral pressure exerted on the back of the face. The result is a innovative, cost saving wall with no mechanical connections necessary.

“You can get strength, longevity, economy, and beauty in one wall system, SRK’s Proprietary Wall System (PCRS) wall. ”

The Process

Excavation

Excavate “slot cuts” into existing sloped embankment

GPS enabled excavator digs slots to line and grade

Slots cut at each counterfort location, typically 15’ on center

Slot cuts are excavated 4 or 5 feet wide with a backslope of ½:1

Slot cut excavation stability is evaluated by the geotechnical engineer

Temporary excavation plan is submitted by the contractor prior to excavating

Installing Counterforts

Installing wall panels

Wall panels are set and secured while backfill is placed

Backfill pressure and friction lock the wall panels in place

Wall panels are typical sizes

Install Miradrain, Fabric and “Burrito” Drain

Place Backfill

We also specialize in:

Caisson Precast Panel Retention System (CPPRS)

Precast Counterfort Retention System + Mechanically Stabilized Embankment

Precast Panel Soundwall System (PPSS)

Mechanically Stabilized Earth (MSE) Walls

Other Precast Retaining Walls